- Mainpage

- Directory

- Nickel alloys

- Thermocouple wire

Alumel - 2.4122 - Nisil® wire

Composition

Alumel is an alloy termoelektrodny, which occupies most of the Nickel to 94%. Also alumel contains cobalt — 1% — to maintain the desired thermoelectric power. Aluminium — not more than 2.5%, manganese — up to 2.2%, silicon in the range of 1.2%. Alumel doped with boron (0,03%) and zirconium (0,06%) is a relatively new alloy.

Dignity

Specific electric resistance is 0.32 Omhm2/m, the melting temperature is 1440 °C, the linear thermal expansion coefficient of 13.7•10-6/°C, a density of 8.48 g/cm3, the annealing temperature is 950 °C. due to the high content in the Nickel alloy-quality of alloy is determined by its physical properties — resistance to corrosion in aggressive environments and at high temperatures. The increase in these properties is achieved by adding alloying elements that stabilize the figure, the thermal EMF increases plasticity provides long-lasting durability and allows the use of this alloy at temperatures up to 1300 °C.

Disadvantages

Alumel is quite expensive because of the rather expensive Nickel. Its main drawback is susceptibility to the ravages of sulfur with increasing temperature that leads to embrittlement and corrosion. This is corrected by increasing the percentage content of silicon and simultaneously reduce the content of aluminum. Such changes increase the duration of the thermocouples at temperatures above 1000 °C.

Use

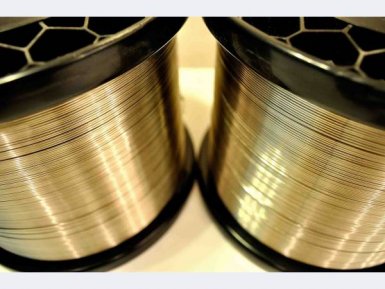

Alumel is widely used in pyrometry in the form of wire and ribbon for the production of thermocouples (wire diameter of 0.2 — 3.2 mm), thermostats and compensation wires. The thermocouple consists of a pair of different conductors, with one end soldered and placed in a medium designed for temperature measurement («hot contact»). The free ends is placed in a thermostat (so-called «cold contact»).

Due to the doping of the thermocouple of this type can withstand brief exposure to temperatures up to 1300 °C when operating in a hostile environment. Alyuminevye compensation wires are used to connect to sensors, as well as to reduce the error of indication. Due to its small size and high accuracy, alumel-chromalive sensors used in the automotive industry, aerospace technology, physical and chemical laboratories.

Supply of alumel brand Nmcac 2−2-1 made in the following form:

Round (D. 12,0 — 100,0 mm);

Wire (D. 0,10 mm to 12,00 mm);

Tape (thick.0.1−5.0 mm wide. 3−600mm).

The chemical composition of the alloy alumel:

| Fe | Co | Mn | Impurities | C | Mn | Al | Ni+Co | Si |

|---|---|---|---|---|---|---|---|---|

| not bol. 0.3 | 0.6 — 1.2 | 1.8 — 2.7 | 0.7 | not bol. 0.1 | 1.8 — 2.7 | 1.6 — 2.4 | 91.5 — 95.15 | 0.85 — 1.5 |

| Physical properties of alumel brand Nmcak2−2-1 at 20 °C | |

|---|---|

| Hardness, hard alloy | HB 10 -1 equal to 250 — 300 MPa |

| Melting point: | about 1440°C |

| Hardness, soft alloy | HB 10 -1 equal to 130 MPa |

| Annealing temperature: | 950°C |

| The temperature of hot processing: | 1050 — 1280°C |

Buy at best price

In stock LLC «AVEK global» in a wide range of ribbons, round wires made of alumel at the best prices. We offer favorable conditions of cooperation. On our website always the latest information. If necessary, advise You experienced managers who will help with this. Product quality is guaranteed by strict observance of the norms of production at all stages. Delivery times are minimal. Wholesale orders are subject to preferential discounts.