- Mainpage

- Directory

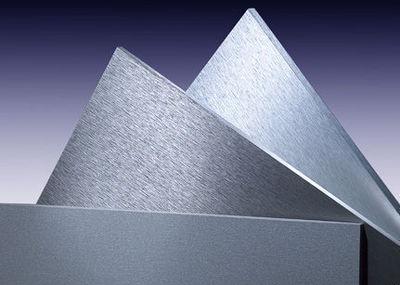

- Stainless steel

- Special purpose steel

08Х21Н6М2Т - эп54 sheet, a circle, a wire

Relevance

The alloy 08Х21Н6М2Т refers to chromium-nickel-molybdenum steels of austenitic-ferritic grade. This alloy is used in the production of distillation columns, extraction, packing, blowing and other containers, storage tanks, tanks, etc. This steel is well used in oxidative reducing environments in acid production, pulp and paper industry and organic synthesis.

The chemical composition of the alloy 08Х21Н6М2Т

| Fe | Cr | C | Mn | P | Ni | Mo | S | Ti | Si |

|---|---|---|---|---|---|---|---|---|---|

| ≤0.8 | Basic. | 20 to 22 | 1.8 to 2.5 | ≤0,025 | ≤0,035 | 5.5 to 6.5 | ≤0.8 | 0.2 to 0.4 |

Production

The production of the alloy 08Х21Н6М2Т is standardized by the following technical conditions 14−3-59−72 and 14−1-894−74, and also GOST: 5582−75; 25054−81; 5632−72; 7350−77; 5949−75. Steel grade 08H21N6M2T is smelted in electric arc furnaces. This alloy is classified as stainless corrosion-resistant ordinary heat-resistant and heat-resistant steel. 08Х21Н6М2Т belongs to the group of austenitic-ferritic steels.

Alloy characteristics at 20 ° С

· Thermal conductivity 0.126 · 10² W / (m · K)

· Density of 7.7 g / cm 3

The modulus of elasticity is 19.3 x 10 -4 N / mm 2

· Hardness — 200 HB MPa -1

· Specific resistance 0,75 Ohmmm 2 / m

· Magnetic permeability in the field of 500 Oe 0.6 (T · m) / A)

Welding

It is carried out by means of automatic; Electric-arc manual and argon-arc welding. Sheet 08Х21Н6М2Т with a thickness of no more than 10 mm is welded by electric arc welding manually satisfactorily. The argon-arc method is recommended for sheets less than 6 mm in thickness and for making root joints thicker than 10 mm. Larger products are satisfactorily welded by two types of arc welding. For the purpose of prevention in welds over 10 mm of hot cracks, the root joints must be welded back-step using welding components without niobium. For a sheet with a thickness of more than 12 mm, a combined method is used (argon-arc welding and welding with piece electrodes).

Electrodes 06X21N6M2T (coating ANV-17) and electrodes S-04X19N11MZ (coating SSSI-13) are well suited for manual welding of steel sheet, thickness no more than 10 mm, and also for filling steel cutting at a thickness of more than 10 mm. With argon-arc manual welding by using non-consumable electrodes of a steel sheet up to 10 mm thick and for the purpose of filling steel sections with a thickness of more than 10 mm, the wire Sv-04Kh19N11MZ is recommended. The strength of weld seams is 90 percent of the base metal. Connections of all types of welding are resistant to intergranular and general corrosion.

Using

Steel grade 08H21N6M2T is used in the production of distillation columns, extraction, packed, purging and other containers, storage tanks, tanks, etc. This steel is well used in oxidative reducing environments in acid production, pulp and paper industry and organic synthesis. Steel is used in the production of acetic, phosphoric and sulfuric acid, melamine, caprolactam, urea. It is necessary for the production of ammonium chloride (by evaporation), in the filtering equipment — sulfite pulp and ammonium sulfate at a temperature of 100−110 ° C with the addition of sulfuric acid to 20 g / l.

Buy at a bargain price

In the warehouse of «Avek Global» LLC there is a wide range of pipes, ribbons, circles and wires of the brand 08H21N6M2T at the best prices. We offer favorable conditions for wholesale and retail deliveries. Our website always has the latest information. If necessary, you will be consulted by experienced managers who will help with the choice. The quality of products is guaranteed by strict observance of production standards at all stages. Terms of supply are minimal. On wholesale orders discounts are provided.