- Mainpage

- Directory

- Titan

- Titan according to GOST

- VT20 alloy pipe

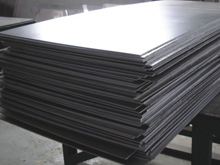

Sheet, rod, round titanium VT20

Advantages of titanium strip, sheet, foil

Brand VT20 — very lightweight, has high strength, heat resistance, hot alloy easily deformed, can be welded all types of welding. Weld strength equals the base metal. The density of this alloy is 4.45 g/cm3, and melting point is 980 — 1020 °C.

| Physical characteristics: | |

|---|---|

| The temperature at which the received data characteristics, °C | 20°C |

| Coefficient of linear thermal expansion αx106 at 100 °C [1/ °C] | 8,2 |

| Density [g/cm3] | 4,45 |

| The modulus of elasticity of 1 kind, E [MPa]x10-5 | 1,12 |

| Specific heat of alloy at 200 °C [j/(kg·deg)] | 0,587 |

| Coefficient thermal conductivity), l[W/(m·deg)] | 8 |

| Electrical resistivity, Mhmm2/m | 1,6 |

Disadvantages

High content of aluminum reduces technological plasticity of the material during pressure treatment.

| Manufacture and dignity plate, sheet stamps VT20 | |||||||

|---|---|---|---|---|---|---|---|

| Prefabricated | Thickness (mm) | Heat treatment | Plasticity of δ% | Strength (MPa) | KCU j/cm3 | ||

| Sheet | 1 — 2 | Annealing | 10 — 12% | 980 — 1130 | --- | ||

| 1 — 5 | 10 | 961 | --- | ||||

| Sheet | 1 — 4 | Delivery condition | More than 8% | 981 — 1180 | --- | ||

| Sheet | 4,5 — 10 | Delivery condition | More than 6% | 981 — 1180 | --- | ||

| Sheet | 1 — 1,8 | Annealing | More than 12% | 932 — 1128 | --- | ||

| 2 — 4 | More than 10% | 932 — 1128 | --- | ||||

| 4,5 — 10 | More than 8% | 932 — 1128 | --- | ||||

| Sheet | 2 MMD | Annealing 800° | 11,3% | 963 | --- | ||

| Annealing | 8% | 1080 | --- | ||||

| Sheet | 2 MMP | Annealing | 7% | 1100 | --- | ||

| Leaves | P | Annealing | 19% | 960 | --- | ||

| D | 21% | 970 | --- | ||||

| Leaves | Annealing | 7 — 10% | 935 — 1080 | ||||

| Sheet, batch rolling | Delivery condition | 6,7 — 8,2% | 997 | ||||

| Plate | 60 — 100 | Annealing | 880 — 1130 | More than 5% | --- | ||

| Plate | 11 — 60 | More than 6% | 930 — 1130 | --- | |||

P — transverse cutting direction samples; D — longitudinal.

Heat resistance is characterized by the highest voltage — creep strength, under whose influence the material is deformed by a given amount at a given temperature.

| Heat resistance of VT20 sheet | ||

|---|---|---|

| Prefabricated | Temperature | The creep strength of 0.2/100 |

Sheet 2 mm |

500°C | 170 MPa |

| 350°C | 550 MPa | |

The fatigue resistance of VT20 sheet

| Sheet | Structure | Thickness (mm) | R | Endurance limit (MPa) 10.000.000 |

Loading |

|---|---|---|---|---|---|

| VT20 | Plate | 1 — 5 3 |

— 1 | More than 412 More than 412 |

Symmetrical loading |

| — 1 |

Use

Semi-finished products made of VT20 alloy used in the annealed condition. They are intended for the production of welded assemblies and products that run over long periods of time at temperatures up to 450 °C. This is the wing skin, parts of GTD, body parts.

Buy at best price

A large range of products from titanium alloy VT20 brand in stock LLC «AVEK global» can satisfy any requests. The price is formed taking into account technological features of production without the inclusion of additional costs. The quality of the finished product is ensured strict compliance with all technological norms of production. The timing of orders is minimal. If you have any questions, you consult experienced managers. For wholesale orders the company provides flexible system of discounts.