- Mainpage

- Directory

- Grids and connections

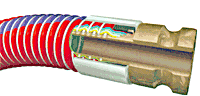

- Metal hose

Table of chemical resistance

Selection factors

The choice of metal hoses for the pipeline section or installation between the equipment is made after determining the optimal length. In addition to the geometric data, it is necessary to take into account the aggressiveness of the transported medium, the internal operating pressure, the temperature, the pulsation of the equipment, the possibility of a hydraulic shock. It is necessary to provide for the conformity of DN, the diameter of the nominal passage, the length of the metal hose along with the ends, the type and brand of the connecting reinforcement. It is assumed that when you purchase the product is of excellent quality, its operation will be long. And given the complexity of the installation site, the overall safety when using metal hoses in aggressive and explosive environments will be complied with its trouble-free operation.

To operate the product does not really bring inconvenience or unforeseen troubles to the user, all established rules of selection, installation and operation should be followed.

Example

Steel AISI 316, in its chemical properties and composition, may not correspond to the transportation of the working environment, in which the AISI 321 pressurized steel hose feels more familiar. If the operating conditions are quite heavy due to high pressure and temperature, the life of the metal sleeve with the inner Steel bellows due to inconsistency of the selected steel grade can be minimal. Well, if a visual inspection of equipment flaw is seen at an early stage. Therefore, when choosing a hose, you should find out how stable this particular product is to the impact of various media. This can be done according to the table of chemical resistance of steels.

Strength of AISI 321 at high temperatures

| Strength limit N / mm 2 (tension), Rp m | 390 | 280 | 329 | 230 | 190 | 140 | |

|---|---|---|---|---|---|---|---|

| Temperature, ° C | 600 | 650 | 700 | 750 | 800 | 850 | |

Recommended maximum temperature for steel 321.

Continuous exposure 900 ° C

Intermittent effects 810 ° C

Tensile strength of grade 316Ti at high temperatures:

| Strength limit N / mm 2 (tension), Rp m | 380 | 270 | 170 | 90 | |

|---|---|---|---|---|---|

| Temperature, ° C | 700 | 800 | 900 | 1000 | |

Recommended maximum temperature for 316Ti steel.

— the action is intermittent 850 ° C;

— exposure to a continuous 925 ° C;

Characteristics of the brand 316Ti at low temperatures:

| Temperature, in | ° C | -161 | -78 | -196 |

|---|---|---|---|---|

The limit is strong. M Rp, N / mm 2 (tension) |

N / mm 2 | 1450/1200 | 1100/950 | 1600/1350 |

Limit of the spine. N / mm 2 Rp 0.2, (0.2%), (fluidity |

N / mm 2 | 380/220 | 300/180 | 400/220 |

| Impact Viscosity | J | 160/160 | 180/175 | 155/150 |

Resistance table

Table of persistence, presented in a graphic form, presents a list of more than seventy names of liquid, solid and gaseous media whose chemical impact on steel has five categories of resistance:

- TC is the boiling point,

- 2 — the use of the sleeve is unacceptable,

- 3 — high degree of corrosion, short service life,

- 4 — satisfactory durability of steel,

- 5 — high resistance.

The use of the data presented in the table will help determine the probability of damage to the metal hose during the service life, which means there is a need to study it before making an order for the acquisition or manufacture of the necessary set of metal sealed hoses.

In order to guarantee the stable operation of metal hoses on the critical sections of industrial facilities, one should turn to professionals who have sufficient experience and can give comprehensive advice on all matters of interest regarding the manufacture and operation of metal hoses.

Buy at a bargain price

LLC «Avek Global» offers the most favorable conditions for the sale of rolled metal. The offered assortment of metal hoses can satisfy any customer. The price depends on the volume of purchase and the additional terms of delivery. By carrying out bulk orders, you can count on the company’s flexible discount system. Our managers are always ready to provide advice. A large assortment will not leave you without a choice. The lead time for orders is minimal. All products are certified. Quality is guaranteed by strict observance of all technological norms of production.